Your White Label Solution for an Immediate Start

Fast track your entry into one of the fastest growing dental segments with an established ceramic implant system, which is both CE-marked and FDA cleared.

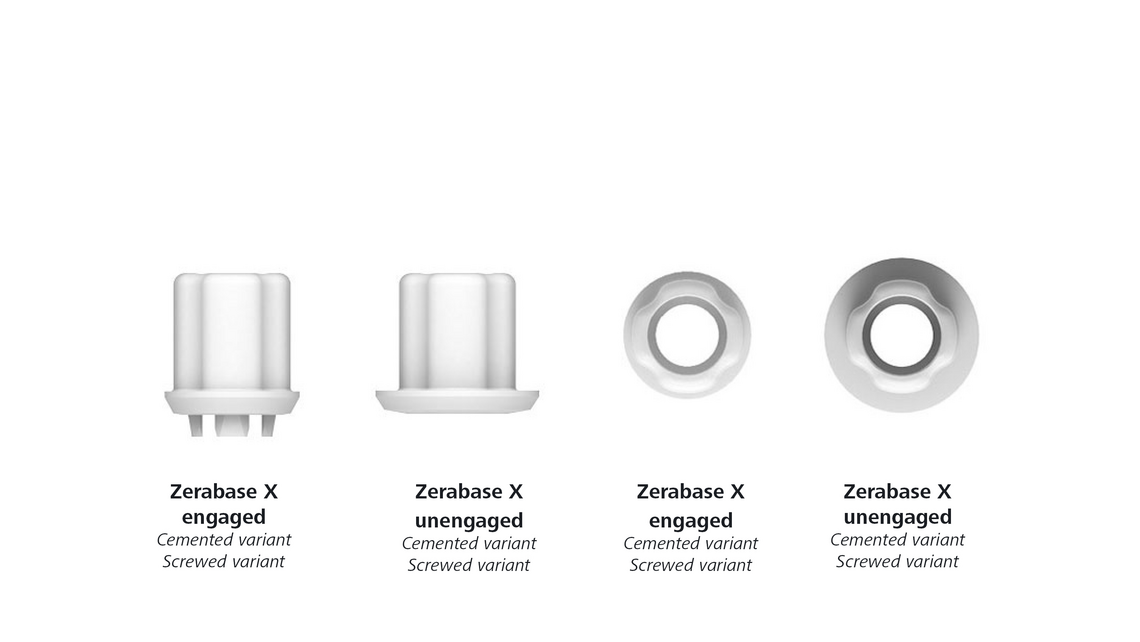

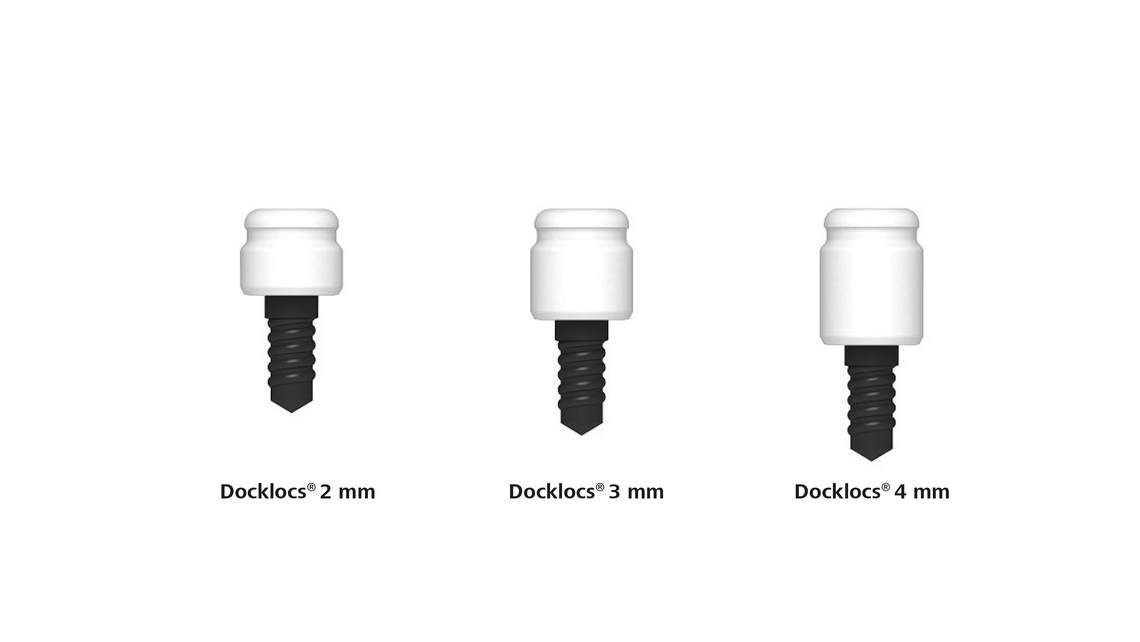

The white label ceramic implant solution offered by CeramTec is an innovative two-piece ceramic implant system - metal-free and cementless. The modular system is based on proven technology* using a reversible screw-in connection for more prosthetic flexibility.

Benefit from more than 10 years of clinical experience in two-piece ceramic implants and extend your portfolio with a ceramic solution predictably, easily and quickly.

The two-piece design offers more flexibility and reversibility compared to one-piece or cemented implant systems.

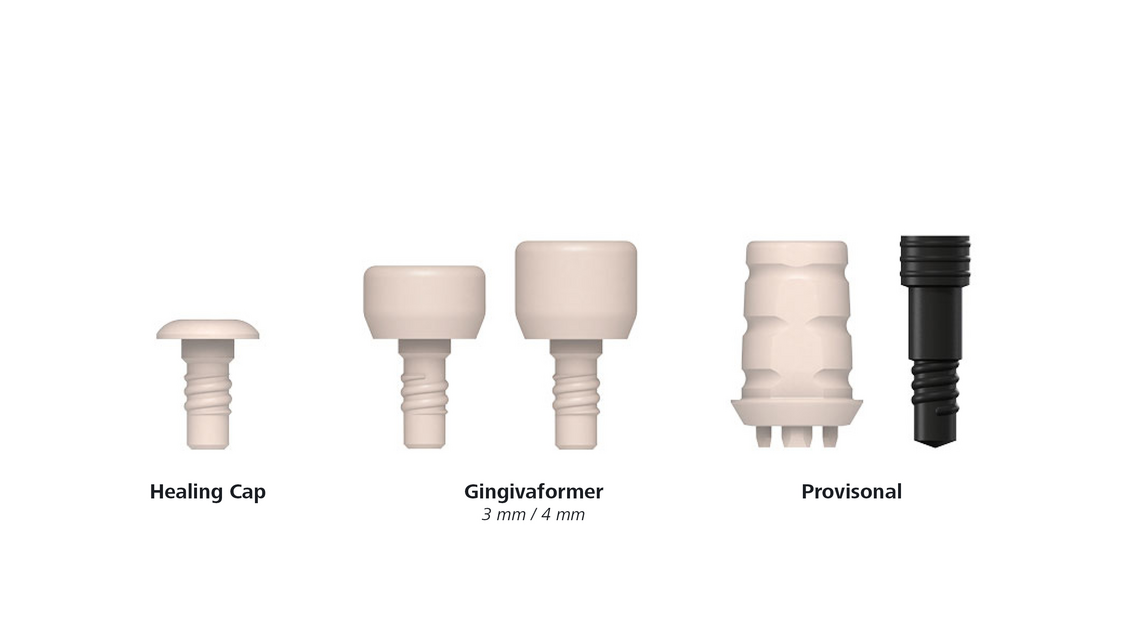

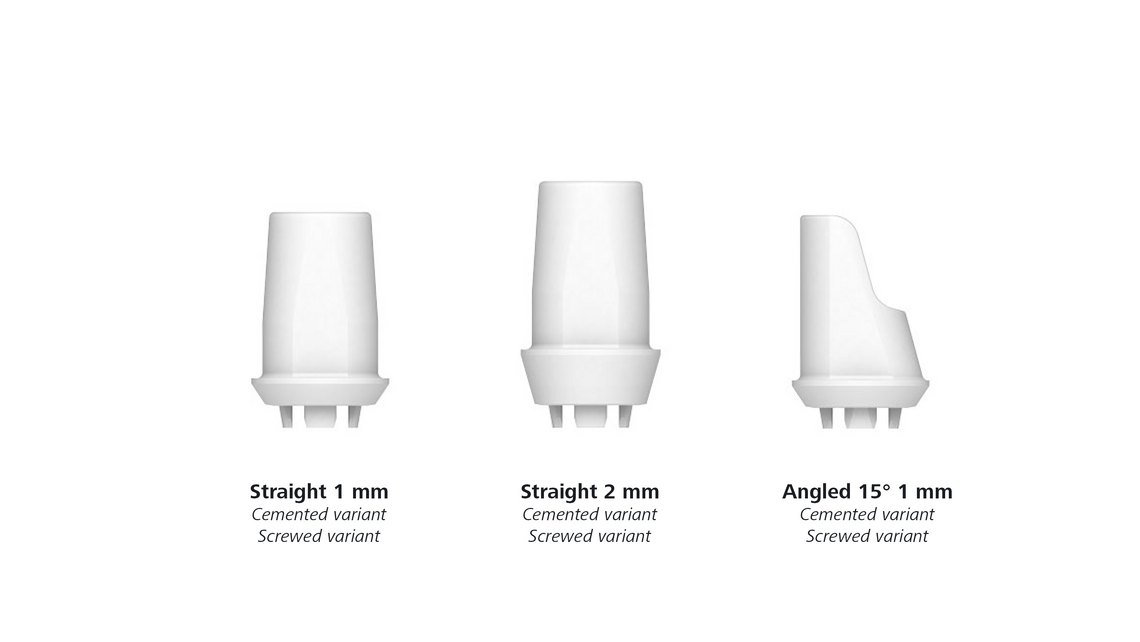

Additionally, there is a wide range of prosthetics available.

The core of the connection is the VICARBO® screw made of carbon-fiber-reinforced high-tech PEEK polymer.

The ceramic implants are hard-machined from hot-isostatic pressed ATZ blanks for maximum precision.

Our complex manufacturing processes ensure that no undesired changes to the material structure can take place.

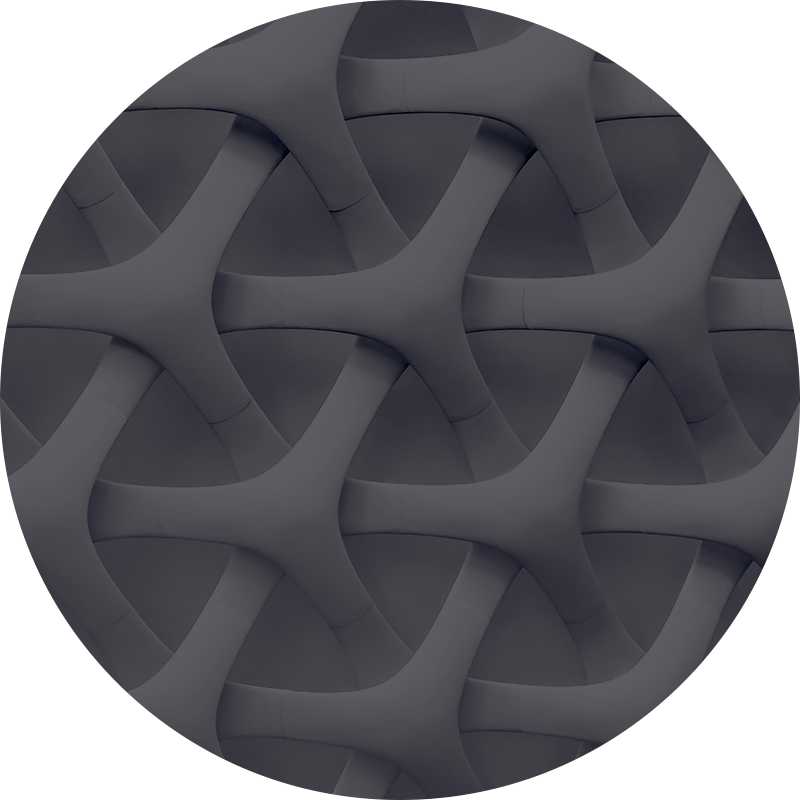

Equipped with the ZERAFIL™ surface to enable decisive osseointegration. The hydrophilic ZERAFIL™ surface is sandblasted and etched to achieve a surface topography enabling enhanced osteoblast adhesion.1

The two-piece design offers more flexibility and reversibility compared to one-piece or cemented implant systems.

Additionally, there is a wide range of prosthetics available.

The core of the connection is the VICARBO® screw made of carbon-fiber-reinforced high-tech PEEK polymer.

The ceramic implants are hard-machined from hot-isostatic pressed ATZ blanks for maximum precision.

Our complex manufacturing processes ensure that no undesired changes to the material structure can take place.

Equipped with the ZERAFIL™ surface to enable decisive osseointegration. The hydrophilic ZERAFIL™ surface is sandblasted and etched to achieve a surface topography enabling enhanced osteoblast adhesion.1