Customised Piezoceramic Components for Critical Medical Systems

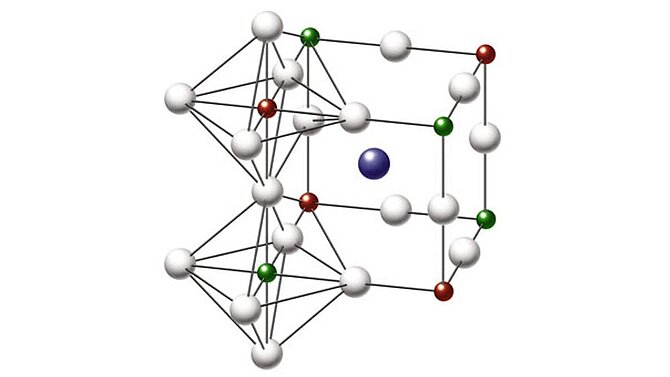

Piezoceramics are used to convert mechanical inputs, such as pressure and acceleration, into electrical outputs or, conversely, to convert electrical signals into mechanical movement or vibration

With three production sites – two in the UK and one in Germany – for piezoceramic components, sensors and transducers, CeramTec is well equipped to provide excellent products for medical applications.

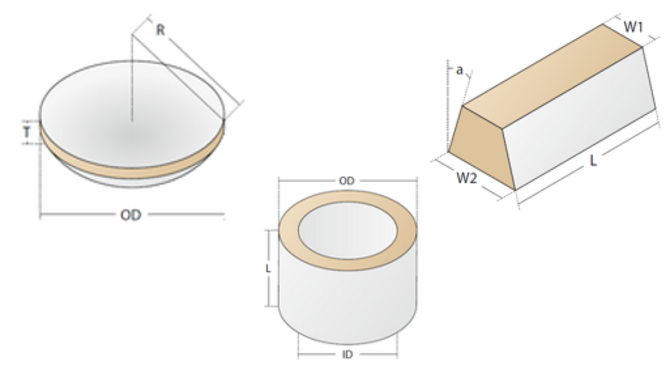

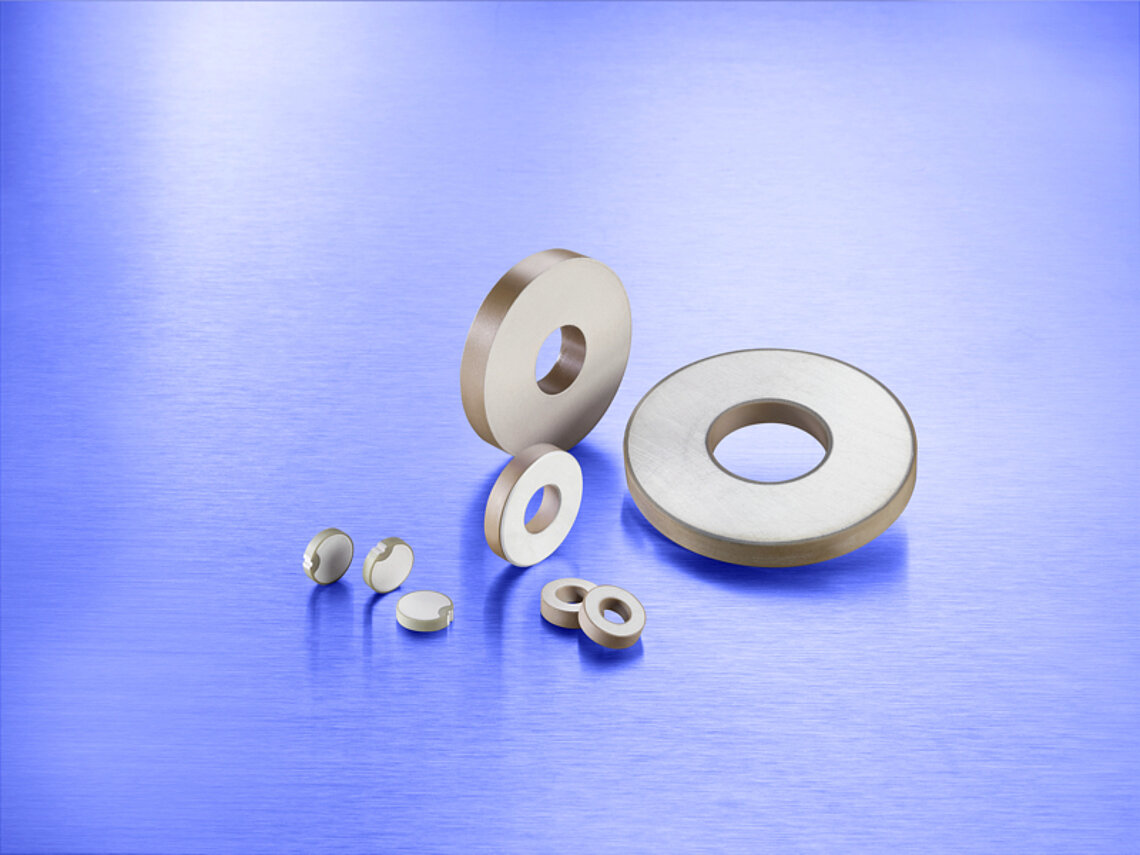

With a selection of more than 20 different piezo material formulations, we are able to offer customer specific solutions for every application. Our metallisation solutions include thick film processes using Ag, evaporation and plating using Ni, Ni/Au, Ni/Cr/Sn.

Dimensional capabilities reach from sub 1 mm to in excess of 250 mm diameter.

We offer high volume, highly automated production with integrated 100 % In-Line inspection as well as craftsmanship production of special components with complex shapes in low volumes.

Future proofing medical devices with advanced ultrasonic technology

In recent years, the medical device sector has seen increasing demand for smaller, more portable devices in response to various challenges the healthcare sector is facing. In this market environment, collaboration between medical device companies and highly specialised component manufacturers is key to provide tailormade solutions.