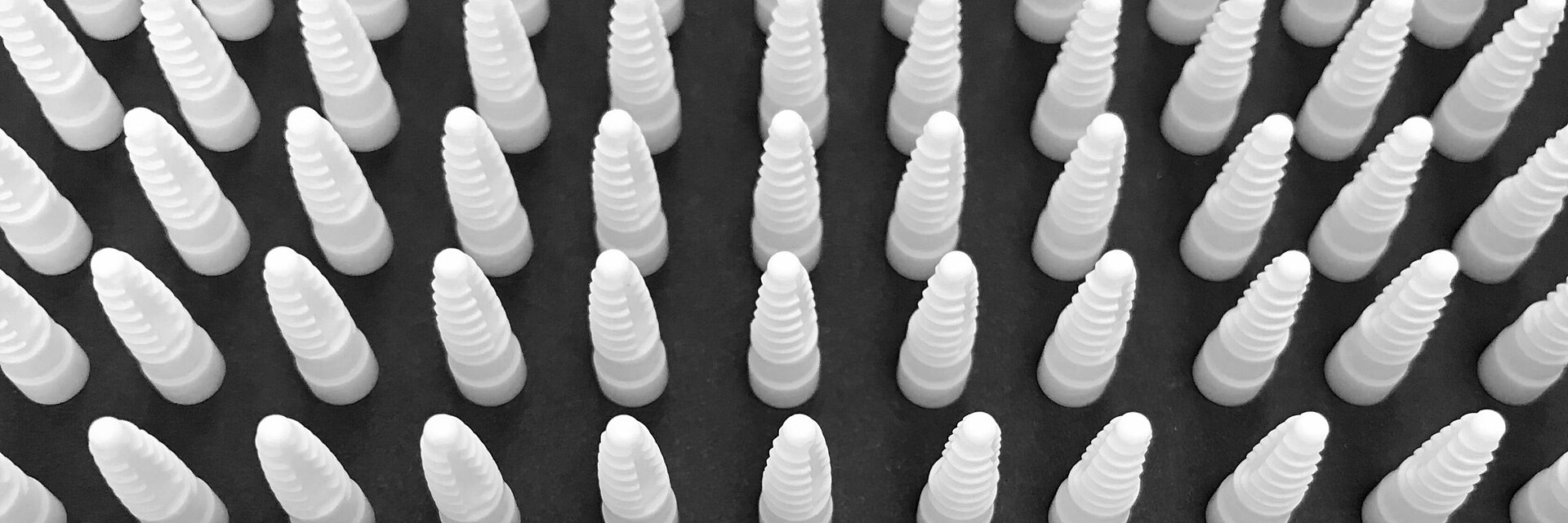

Pure, Precise and Clean

The manufacturing process of medical grade ceramics is more demanding than the process for metal solutions. Successful new product introduction requires efficient, goal-driven processes while maintaining the highest quality standards. This applies equally to the manufacturing of prototypes, pilots and large-scale production.

CeramTec has the resources, expertise and competence to manufacture your products according to your requirements without compromising quality. Our expertise in ceramic manufacturing is based on decades of research and development of efficient production processes and we continuously explore innovative and more cost-effective manufacturing technologies.

We Stand for Quality

All custom made DENSILOX® implants are class IIb implants (in the EU), manufactured and 100% inspected in our facilities in Germany. We have different manufacturing technologies on offer according to your preferences: Hard machining, green machining, ceramic injection moulding or a combination of the above. Our clean-room packaging ensures contaminant-free clean implants with the option of sterile packaging as an additional service. All customized ceramic implant solutions produced in our facilities in Germany are certified with the 2023 CleanImplant supplier label.

Conventional Manufacturing

Years of experience have made our conventional manufacturing (green machining, hard machining) the most responsive and efficient in the production of ceramic surgical implants.

We can also offer hybrid production routes according to your needs with a combination of green machining, hard machining and ceramic injection moulding.

- Implants (one piece or two piece)

- Abutments

- Semi-finished products

Ceramic Injection Moulding

Our CIM technology is fully integrated in our quality management system. CeramTec’s ceramic injection moulding is processed under controlled environment.

CIM manufacturing technologies are the go-to choice for large volume production.

- Implants (one piece or two piece)

- Abutments

- Semi-finished products

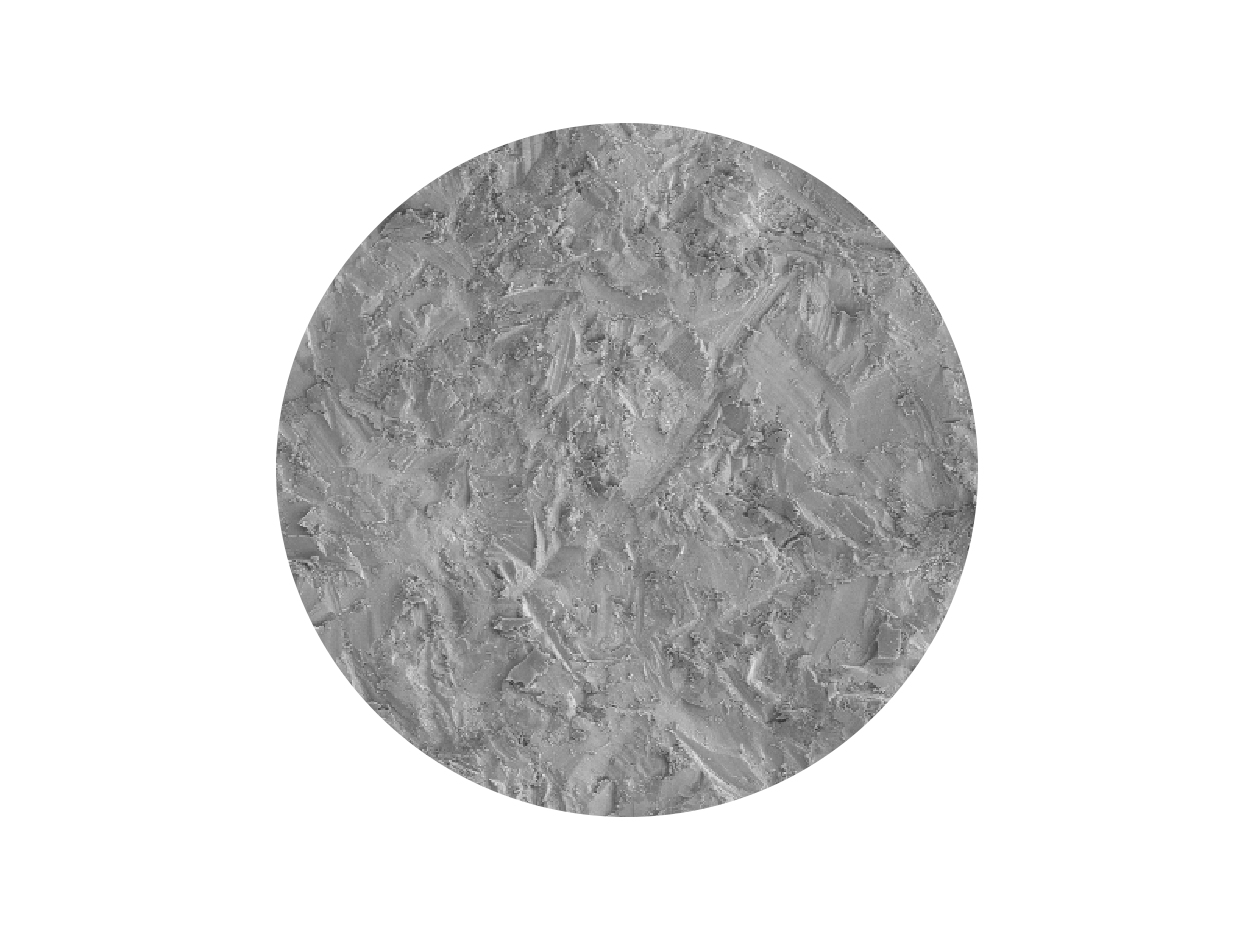

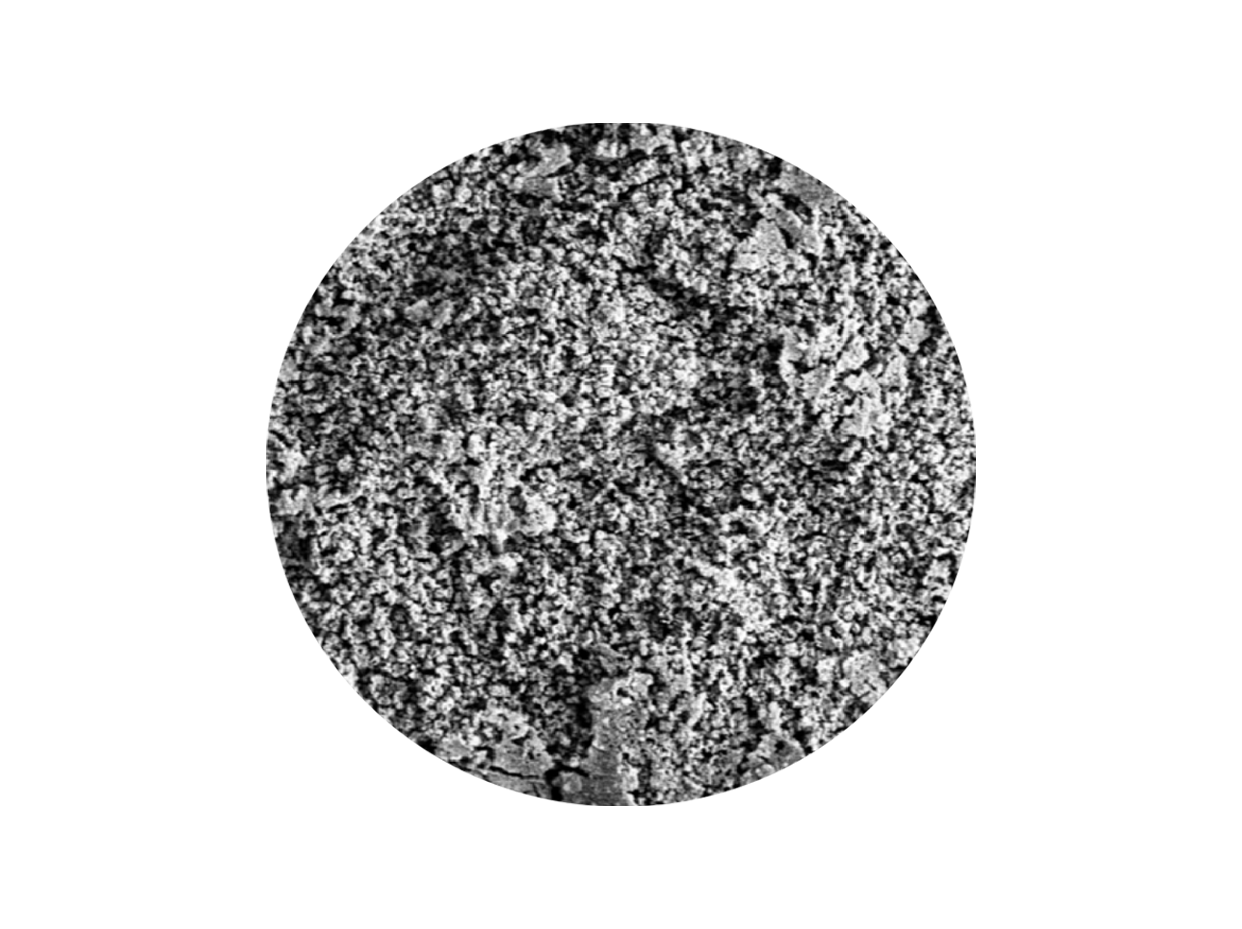

Successful dental implantation is primarily governed by good osseointegration. Rough surfaces have demonstrated to promote osseointegration. Sandblasting and acid etching are some of the most used surface treatments to generate micro- and nano-structured surfaces on dental implants to improve the implant's surface bioactivity. The symbiotic effect of sandblasting and acid etching creates a rough ceramic surface which accelerates osseointegration.1